A Unified Platform for Condition-based Maintenance

Everlytics is changing the way manufacturing companies monitor and maintain their equipment, through the next-generation software platform and AI.

A single-window monitoring of all your equipments’ health with alerting facility.

An interface for root cause analysis & correlated insights to aid repair.

Inbuilt AI engine identifies failures before they occur. The AI engine learns from past data and self-improves with new data.

Our strategy is to first educate, show you the proof of value, and then scale!

REQUEST A DEMOWhat’s More?

The platform comes with these other optimization solutions that can easily be tailored to your process. Our objective here is to solve your other basic operational problems that are sometimes more important than predictive maintenance itself.

Utilization Optimization

Productivity Optimization

Predictive Capacity Planning

Who is it for?

This works across industries and for a wide variety of machines. Depending on where you are in the journey of automation and 4.0, Everlytics shall work with you and propose an implementation strategy that fits you.

Why do you need it?

The first powerful car came out in 1860 with the invention of IC engine. However, it was not until 1959 they started fitting seat belts to cars. It’s time your machines too need a predictive maintenance belt to avert costly failures. Because,

Time-based maintenance is costly & inefficient

Downtime directly affects bottom line

Humans can’t do it alone anymore with increased complexity and scale of the infrastructure

Benefits...

Increased asset production

Lower maintenance costs

Exceed availability targets

Better control over the process

REQUEST A DEMOHow it works?

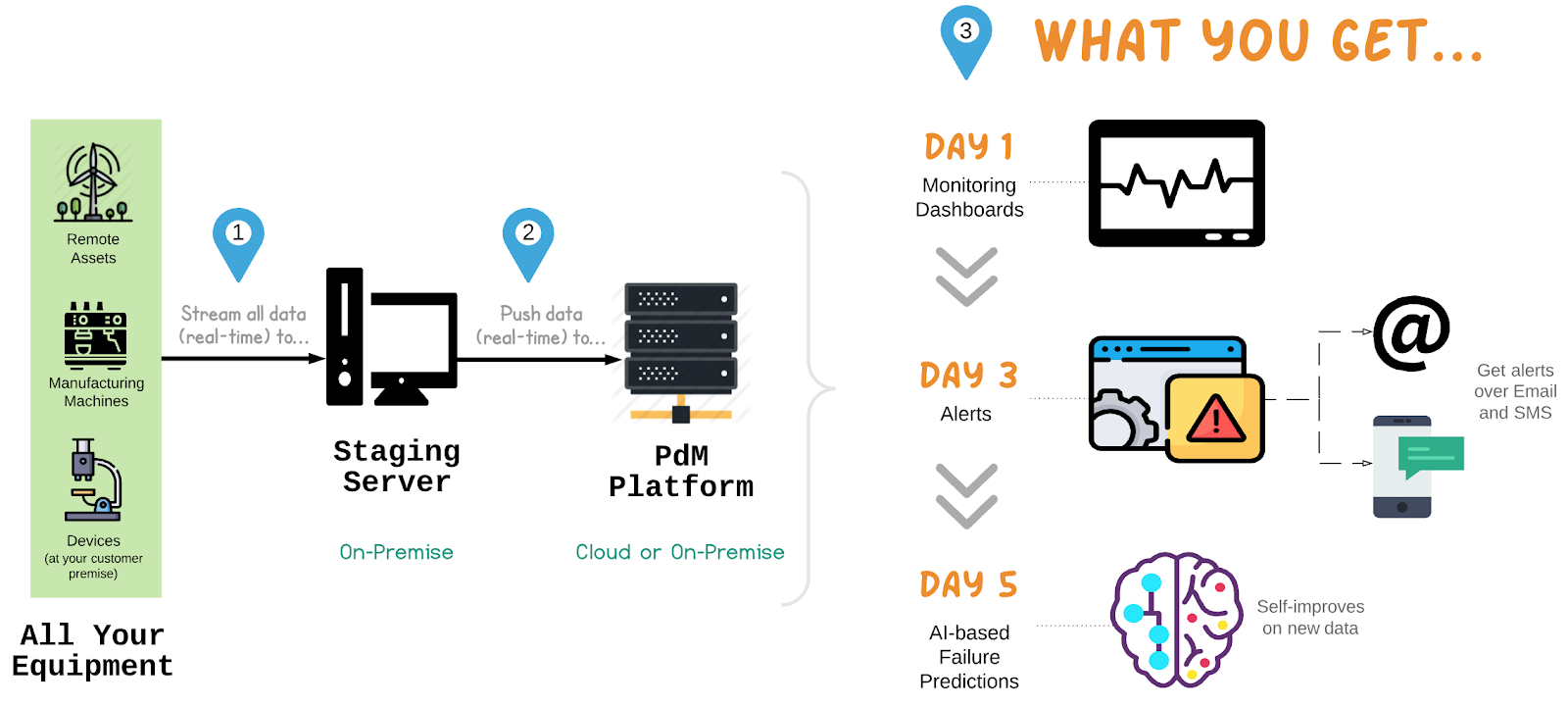

- Everlytics will first set up the necessary connectivity between your machines and our platform. With this, condition data starts flowing to the platform in real time.

- Immediately next you will see the Monitoring Dashboards and on day 3 (after we configure the thresholds) you will start receiving machine health Alerts.

- The AI engine kicks in on day 5 with predictions on impending failures. Other modules viz. Utilization, Productivity and Capacity optimization will be ready in a few days from there after we configure the necessary metadata specific to your process.

.png)

.png)